Flexitanks for Liquids

Multi-Layered Flexitanks

Multi-layered Flexitanks (also referred to as Flexitanks, Flexibags, Flexible bags, Liquid liners, Liquid bags, Bags or Tanks) are used inside 20’ or 40’ containers and converts the shipping container into a bulk liquid transport solution for free-flowing non-hazardous liquids. Various loading and unloading valve types and sizes can be requested. The Flexitank is retained safely inside the container doors by a Bulkhead and steel bulkhead bar or Steel Frame system.

A wide range of products can be transported in our Flexitanks including juices, food oils (such as olive oil, sunflower oil and palm oil), butters (such as shea butter and cocoa butter), Wine, Latex and many Industrial and chemical products.

Overview

- Our Multi-layered Flexitanks are available in sizes ranging from 10,000 to 24,000 litres.

- Can be configured for Top Loading/ Discharge, Bottom Loading/Discharge, or Top Loading & Bottom Discharge.

- Capable of carrying a wide range of free-flowing non-hazardous liquids, both food-grade and non-food grade.

- 100% Food Grade contact materials.

- Our Flexitanks are manufactured in our ISO9001 / ISO14001 / ISO22000 (ISO – Standards) quality-assured plants with strict raw material testing, QA procedures and controls.

- Our Flexitanks are manufactured and tested in accordance with PAS1008:2016.

- Aseptic Flexitanks are available for products like natural juices loaded under Aseptic conditions (read more about Aseptic Processing here)

Materials

- Food-grade, high-tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties specifically formulated for Flexitanks use.

- High-Strength Woven Polypropylene fabric outer layer.

- Food-grade Polypropylene 3” Filling/Discharge Valve (other sizes available).

- Optional barrier layers for products susceptible to oxygen and odour transmission.

Features

- Our Flexitanks are made from seamless PE films to reduce the number of welds.

- Automatic Pressure Release Valve (PRV) available.

- 100% of all Flexitank end welds are pressure tested to 1 bar.

- All materials are fully recyclable.

- Flexible and easy to roll up after discharge.

- Easy to install; with valve positioning fittings.

- Our Flexitanks are industry-leading, extra durable with a superior safety record.

- Corrugated board and metal bar bulkhead or Steel Frame system for secure transport.

- Bathtub-style lining available as an additional safety feature.

- Various agitation systems can be used for Suspension liquids that separate and need re-mixing.

Single-Layered Flexitanks

Our Single-layered Flexitanks are used inside 20’ containers and convert the shipping container into a bulk liquid transport solution for free-flowing non-hazardous liquids. Robust and easily recyclable, they also perform well when shipping very viscous products. The Flexitank is retained safely inside the container doors by a Bulkhead and steel bulkhead bar or Steel Frame system.

Overview

- Our Single-layered Flexitanks are available in sizes ranging from 10,000 to 24,000 litres.

- Can be configured for Top Loading/ Discharge, Bottom Loading/Discharge, or Top Loading & Bottom Discharge.

- Capable of carrying a wide range of free-flowing non-hazardous liquids, both food-grade and non-food grade.

- 100% Food Grade contact materials.

- Our Single-layered Flexitanks are manufactured in our ISO9001 / ISO14001 / ISO22000 (ISO – Standards) quality-assured plants with strict raw material testing, QA procedures and controls.

- Our Flexitanks are manufactured and tested in accordance with PAS1008:2016.

Materials

- Food-grade, high-tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties, specifically formulated for Flexitank use.

- Food-grade Polypropylene 3” Filling/Discharge Valve (other sizes available).

- Optional barrier layers for products susceptible to oxygen and odour transmission.

Features

- Automatic Pressure Release Valve (PRV) available.

- All materials are fully recyclable.

- Our Flexitanks are industry-leading, extra durable with a superior safety record.

- Easy to install; with valve positioning fittings.

- Corrugated board and metal bar bulkhead or Steel Frame system for secure transport.

- Bathtub-style lining available as an additional safety feature.

- Internal elbow to aid full discharge of cargo.

- Single layer design suitable for viscous and difficult to discharge products. Designed for discharge with powerful high-suction pumps.

- Semi-transparent material aids product visibility whilst loading.

- Various agitation systems can be used for Suspension liquids that separate and need re-mixing.

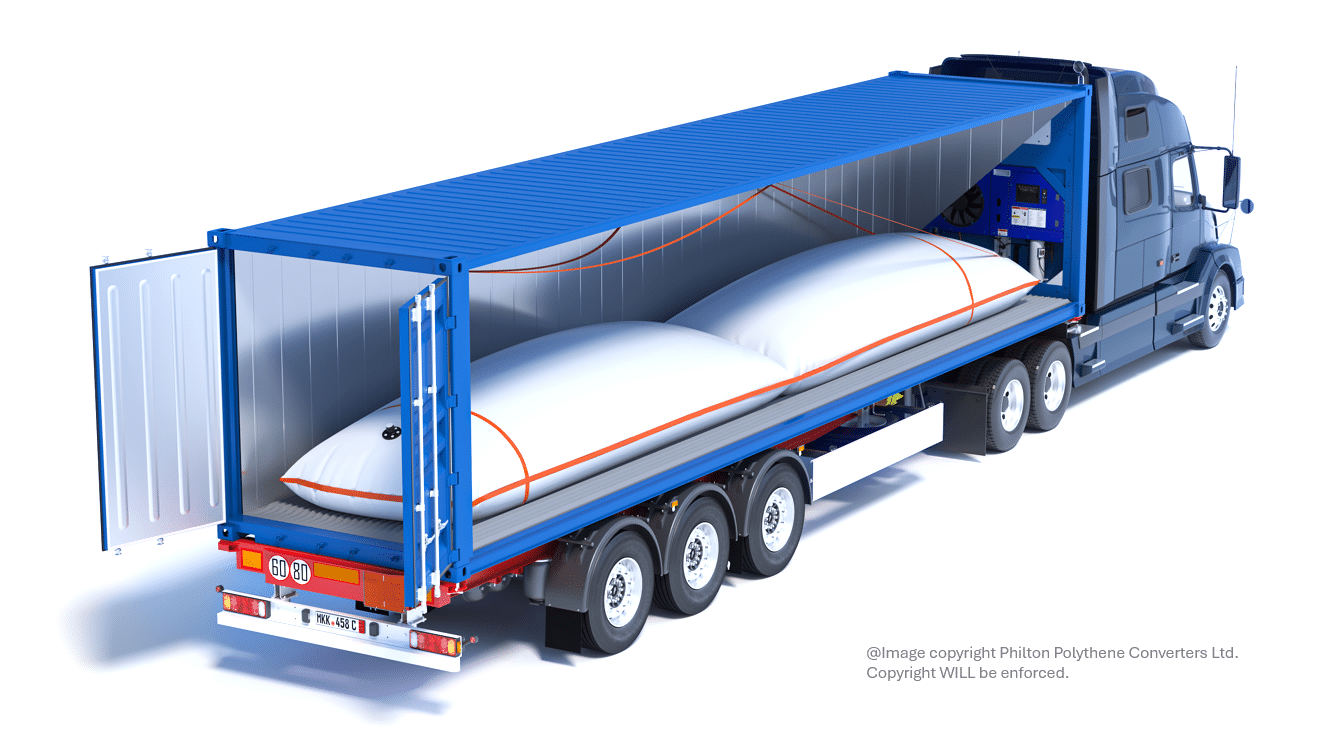

Trailer Flexitanks / Reefer Flexitanks / 40’ and 45’ Flexitanks

Our Multiple chamber Flexitanks are installed into 40’ and 45’ Sea containers, curtain-sided trailers, swap bodies, Frigo or reefer trucks or reefer Containers (for more about trailer types – see here) to convert them into a bulk liquid transport solution for free-flowing, non-hazardous liquids. They come in various capacity sizes to suit the product being loaded.

The multiple chambers stop large volumes of liquid moving up the length of the container which could pose risks.

Overview

- Our Trailer Flexitanks/Reefer Flexitanks/40′ and 45′ Flexitanks are available in sizes ranging from 5,000 to 27,000 litres.

- Customisable for various sizes, including 30’, 40’ and 45’ containers or trailers.

- Capable of carrying a wide range of free-flowing non-hazardous liquids, both food- grade and non-food grade.

- 100% Food-Grade contact materials.

- Our trailer Flexitanks are manufactured in our ISO9001 / ISO14001 / ISO22000 (ISO – Standards) quality-assured plants with strict raw material testing, QA procedures and controls.

- Our Flexitanks are manufactured and tested in accordance with PAS1008:2016.

- Aseptic Flexitanks are available for products like natural juices loaded under Aseptic conditions (read more about Aseptic Processing here)

Materials

- Food-grade, high-tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties, specifically formulated for Flexitank use.

- High-Strength Woven Polypropylene fabric.

- Food-grade Polypropylene 3” Filling/Discharge Valve as standard (other sizes are available).

- Optional barrier layers for products susceptible to Oxygen and odour transmission.

Features

- Our Flexitanks made from seamless PE films to reduce the number of welds.

- Our Flexitanks are industry-leading, extra durable with a superior safety record.

- Automatic Pressure Release Valve (PRV) available.

- 100% of all Flexitank end welds are pressure tested to 1 bar.

- All materials are fully recyclable.

- Easy to install with a unique surge-damping system.

- Ideal for when 20’ shipping containers are not readily available, or when road tankers are not commercially viable.

- Special designs available using PPC Philton’s proprietary Anti-surging technology.

- Special designs available using PPC Philton’s reusable Harness system.

Special Design Flexitanks

We provide specially designed and bespoke Flexitank systems for demanding projects with some unique and innovative solutions to assist loading and unloading difficult liquid and solid products.

Overview

- The size and specification of our Special Design Flexitanks can be tailored to meet the application.

- Can be configured for Top Loading/ Discharge, Bottom Loading/Discharge, or Top Loading & Bottom Discharge.

- Capable of carrying difficult-to-discharge non-hazardous liquids, or Suspension liquids that separate and need re-mixing.

- 100% Food Grade contact materials.

- Our Flexitanks are manufactured in our ISO9001 / ISO14001 / ISO22000 (ISO – Standards) quality-assured plants with strict raw material testing, QA procedures and controls.

- Our Flexitanks are manufactured and tested in accordance with PAS1008:2016.

- Aseptic Flexitanks are available for products like natural juices loaded under Aseptic conditions (read more about Aseptic Processing here)

Materials

- Food-grade, high-tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties, specifically formulated for Flexitank use.

- High-Strength Woven Polypropylene fabric outer layer.

- PVC coated woven fabric.

- Numerous options for filling, discharge and venting available.

- Optional barrier layers to protect against radiant heat, sunlight, oxygen and odour transmission.

Features

- Our Flexitanks are made from seamless PE films to reduce the number of welds.

- Our Flexitanks are industry-leading, extra durable with a superior safety record.

- Automatic Pressure Release Valve (PRV) available.

- Special bulkhead systems to optimise a fast and easy unloading.

Static Storage Tanks

Our containerised or ground storage tanks are suitable for temporary storage of water and a wide range of food-grade and Industrial liquids.

Overview

- Our Static Storage Flexitanks are available in sizes up to +50,000 litres.

- Capable of storing a wide range of free-flowing, non-hazardous liquids, both food-grade and non-food grade.

- 100% Food Grade contact materials.

- Our Static Storage Tanks are manufactured in our ISO9001 / ISO14001 / ISO22000 (ISO – Standards) quality-assured plants with strict raw material testing, QA procedures and controls.

- Our Flexitanks are manufactured and tested in accordance with PAS1008:2016.

- Ideal for outdoor festival use for water or waste slurry.

- Ideal for water distribution and storage in drought and war affected areas.

- Ideal for static water storage for emergency firefighting in remote areas.

- Temporary static containerised storage during plant refurbishments, shutdowns or for production requirements.

Materials

- Food-grade, high-tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties.

- High strength Woven Polypropylene fabric.

- Food-grade Polypropylene 3” Filling/Discharge Valve (other sizes available).

- Coated PVC woven fabric.

Features

- Our Static Storage Tanks are made from seamless PE films to reduce the number of welds.

- Our Flexitanks are industry-leading, extra durable with a superior safety record.

- All materials are fully recyclable.

- Optional ground Sheet available for added protection.

- Additional valves, vents and drains can be placed on the Storage tank as required.

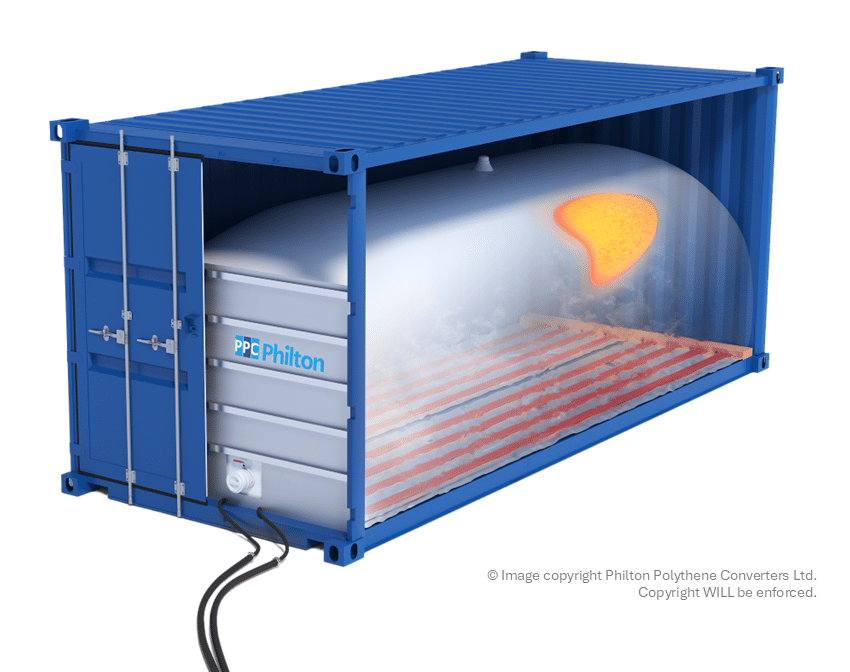

Heater Pads

Our Heater pads are used to re-liquify any liquid that has solidified during transportation ready for discharge.

Overview

- Our Heater Pads are available in any size or capacity to meet your requirements.

- Our Heater Pads are manufactured in our ISO9001 / ISO14001 / ISO22000 (ISO – Standards) quality-assured plants with strict raw material testing, QA procedures and controls.

- Used to heat a wide variety of products, including food oils and butters (such as shea Butter, Cocoa Butter, Palm Oil and Coconut oil), molasses, heavy greases, Fatty Acids and Waxes.

Materials

- Heat reflecting foil base to direct the heat into the product and protect the container floor.

- Superior quality heater hose capable of maintaining a higher steam temperature than standard heater pad systems.

Features

- Safe and easy to use with hot water or low-pressure steam.

- Can be used in conjunction with any of our Flexitanks.

- Includes a unique test system to ensure correct operation.

- Quick and easy to install.