Dry Bulk Container Liners

Back Fill Liners

Converts any Shipping line Container for the bulk transportation of most free flowing non-hazardous products.

Overview

- Can be Installed inside any size shipping container.

- Loaded from the door end using a belt thrower, pneumatic pump, conveyor, or elevated to load under gravity depending on the loading system, or product being loaded.

- Capable of carrying a huge range of free flowing granular, powder, pellet or flaked products, both food grade and Industrial grade.

- Designed for loading or discharge with one, or both doors open.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Food grade high tensile co-extruded LLDPE film offering excellent moisture (Water vapor transmission rate – WVTR) barrier properties.

- Woven HDPE or Woven PP fabrics offering high strength at a low cost.

- Antistatic / Dissipative Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) barrier properties as well as static control properties.

Features

- Made from seamless PE films or wider width woven fabrics to reduce the number of joins.

- PPC Philton liners are best in class, extra durable with a superior safety record.

- Fast and easy to install.

- PPC Philton liners maximize the container payload, reduce costs, and minimize the environmental impact. All component parts are 100% recyclable.

- Any number of loading and venting spouts can be fitted to suit the customers’ requirements in any shape or size. Wide access Zippers for conveyor loading are also available.

- Discharge via gravity, or pump.

- Any number of discharge spouts can be fitted to suit the customers’ requirements in any shape or size.

- Airbags can be added to aid discharge.

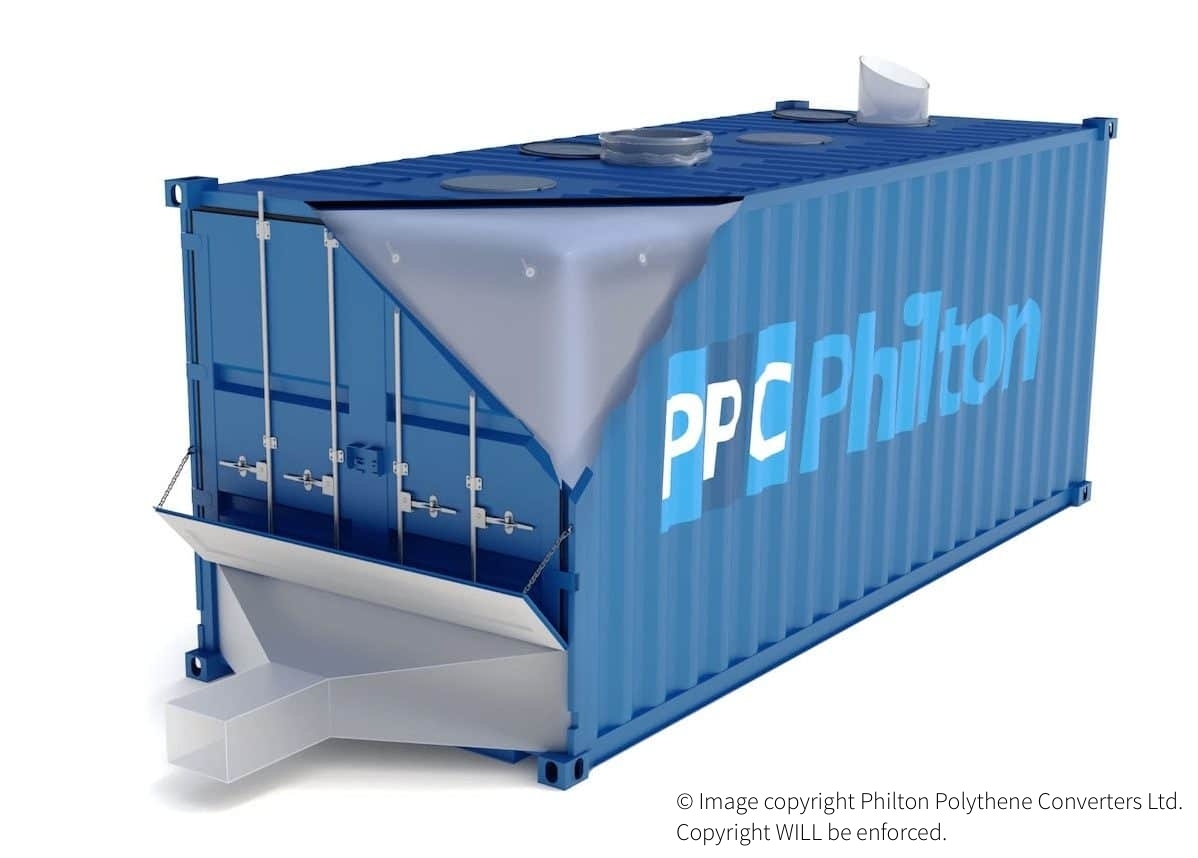

Top Fill Liners

Enables a Bulker Container to be used for bulk transportation or storage of most free flowing non-hazardous products.

Overview

- Can be Installed inside any size bulk container.

- Loaded from the top hatches via gravity fill or via a single hatch with a spreader system.

- Capable of carrying a huge range of free flowing granular, powder, pellet or flaked products, both food grade and Industrial grade.

- Designed for discharge via the letterbox hatch or hatches at the base of the container end.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Food grade high tensile co-extruded LLDPE film offering excellent moisture (Water vapor transmission rate – WVTR) barrier properties.

- Woven HDPE or Woven PP fabrics offering high strength at a low cost.

- Antistatic / Dissipative Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) barrier properties as well as static control properties.

Features

- Made from seamless PE films or wider width woven fabrics to reduce the number of joins.

- PPC Philton liners are best in class, extra durable with a superior safety record.

- Fast and easy to install.

- PPC Philton liners maximize the container payload, reduce costs, and minimize the environmental impact. All component parts are 100% recyclable.

- Any number of loading spouts can be fitted to suit the customers’ requirements.

- Discharge via gravity.

- Fishtail discharge spout is standard, but other wide access spouts are available to suit the customers’ requirements.

- Airbags can be added to aid discharge.

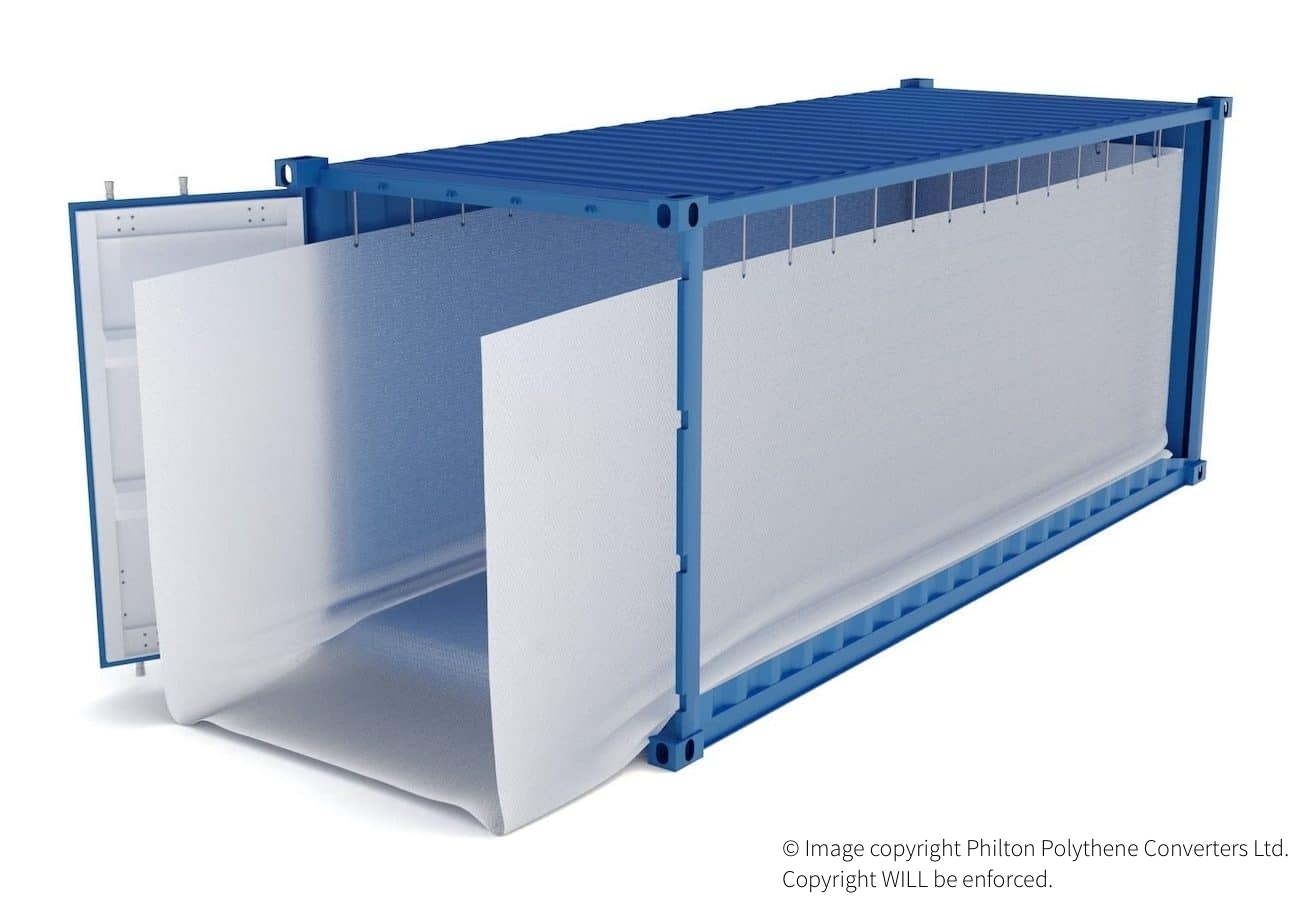

Open top / Open ended Liners

Allows any Container, Trailer or Railcar to safely transport many bulk non-hazardous cargoes.

Overview

- Can be Installed inside any size shipping container, trailer, or railcar.

- Open ended, open top, top loading or end filling via loading spouts.

- Capable of carrying a huge range of free flowing, palletized or packed products, both food grade and Industrial grade.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Food grade high tensile co-extruded LLDPE film offering excellent moisture (Water vapor transmission rate – WVTR) barrier properties.

- Woven HDPE or Woven PP fabrics offering high strength at a low cost.

- Antistatic / Dissipative Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) barrier properties as well as static control properties.

Features

- Made from seamless PE films or wider width woven fabrics to reduce the number of joins.

- PPC Philton liners are best in class, extra durable with a superior safety record.

- Fast and easy to install.

- PPC Philton liners maximize the container payload, reduce costs, and minimize the environmental impact. All component parts are 100% recyclable.

- Open ended, open top or manufactured with any number of loading and venting spouts to suit the customers’ requirements in any shape or size. Wide access Zippers for conveyor loading are also available.

- Discharge via gravity, or suction pump for free flowing products or Fork truck for palletized goods.

Foil Liners

When installed inside a Container, the PPC Philton Foil Liner provides a controlled climate for the cargo.

Overview

- Can be Installed inside any size shipping or bulk container.

- Open ended, top loading or end filling via loading spouts.

- Excellent protection for products which may deteriorate due to odour, light, oxygen or moisture ingress.

- Discharge arrangements to suit the customers requirements.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Aluminum barrier foil laminate co-extruded PE / PET /Aluminum Foil / co-extruded PE.

- Woven PP bulkhead for End filling liners.

Features

- Superior protection for sensitive products compared to PE film or Woven liners.

- Up to 80 times more effective than 125mu PE film at preventing moisture damage.

- Fast and easy to install.

- PPC Philton liners are best in class, extra durable with a superior safety record.

- Foil liners can be completely sealed for airtight containment.

- Open ended, or any number of discharge spouts can be fitted to suit the customers’ requirements in any shape or size.

Barless Liners

Converts any shipping line container for the bulk transportation of most free flowing non-hazardous products.

Overview

- Can be Installed inside any size shipping container.

- Loaded from the door end using a belt thrower, pneumatic pump, conveyor, or elevated to load under gravity depending on the loading system, or product being loaded.

- Capable of carrying a huge range of free flowing granular, pellet or flaked Industrial grade products.

- Designed for loading or discharge with one, or both doors open.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Woven HDPE or Woven PP fabrics offering high strength at a low cost.

- Antistatic / Conductive fabric grades are available.

Features

- Made from wider width woven fabrics with internal baffles to retain the load.

- Fast and easy to install.

- PPC Philton liners maximize the container payload, reduce costs, and minimize the environmental impact. All component parts are 100% recyclable.

- Any number of loading and venting spouts can be fitted to suit the customers’ requirements in any shape or size. Wide access Zippers for conveyor loading are also available.

- Discharge via gravity, or pump.

- Any number of discharge spouts can be fitted to suit the customers’ requirements in any shape or size.

- Airbags can be added to aid discharge.

Fluidising Liners

Enables ‘hard to flow’ non-hazardous products to be easily discharged from a Container.

Overview

- Can be Installed inside any size shipping or bulk container.

- Full or partial fluidisation available. Can be controlled section by section, or either end of the container.

- Capable of carrying a huge range of hard to flow and compactable products such as fly ash, Calcium carbonate, flour and talc.

- Increases the range of products that can be transported.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Virgin Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties.

Features

- Made from seamless Heavy duty PE films to reduce the number of welded seams.

- Unique flat floor system avoids bridging points made by hoses, as seen on inferior designs.

- Fast and easy to install.

- Quickly fluidises heavily compacted product to allow an easy flow and controlled discharge.

- PPC Philton liners are best in class, extra durable with a superior safety record.

- PPC Philton liners maximize the container payload, reduce costs, and minimize the environmental impact. All component parts are 100% recyclable.

- Any number of loading and venting spouts can be fitted to suit the customers’ requirements in any shape or size.

- Discharge via gravity using air for the fluidising system.

- Generally used with larger discharge spouts.

- Airbags can be added to aid discharge.

Thermal Liners

When installed inside a container, the PPC Philton Thermal liner reduces the peaks and troughs of climatic change.

Overview

- Can be Installed inside any size shipping or bulk container.

- Open ended to allow palletized or loose packed goods to be stowed.

- Full width and height access for loading.

- Excellent protection for products which may deteriorate due to radiant heat.

- PPC Philton liners are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Woven Aluminum barrier foil laminate co-extruded PE / PET /Aluminum Foil / co-extruded PE.

- Aluminum foil bubble laminate.

Features

- Superior protection for sensitive products compared to PE film or Woven liners.

- Fast and easy to install.

- Reflects over 90% of radiant heat to stop temperature peaks and troughs from damaging sensitive cargo.

- Zipper or Velcro closure system.

- PPC Philton liners are best in class, extra durable with a superior safety record.

Bulkhead sheets

Converts any Shipping Line Container for the bulk transportation of most low cost non-hazardous bulk products.

Overview

- Can be Installed inside any size shipping container.

- Loaded from the door end using a belt thrower, pneumatic pump, conveyor, or elevated to load under gravity depending on the loading system, or product being loaded.

- Capable of carrying a huge range of free flowing granular, powder, pellet or flaked products, both food and Industrial grade.

- Designed for loading or discharge with one, or both doors open.

- PPC Philton bulkhead sheets are manufactured in our ISO9001 / ISO22000 quality assured plants with strict raw material testing, QA procedures and controls.

Materials

- Woven HDPE or Woven PP fabrics offering high strength at a low cost.

Features

- Very low-cost system for loading products not requiring total containment.

- Fast and easy to install.

- Discharge via the ‘rip and tip’ method, or via a discharge spout.